Get a quote today

Send your details inquiry on cable trays and get a response soon.

Wire Mesh Cable Tray Detailed Information

WIRE MESH CABLE TRAY Surface Finish

Perforated Cable Tray

It has three load carrying capabilities: Heavy Duty Return Flange, Medium Duty Return Flange and Light Duty. And offer a good ventilation to cables, are generally used for moderate heat generating electrical or telecommunication applications.

It has three load carrying capabilities: Heavy Duty Return Flange, Medium Duty Return Flange and Light Duty. And offer a good ventilation to cables, are generally used for moderate heat generating electrical or telecommunication applications. View More

Wire Mesh Cable Tray

Trays shall be supported at a maximum span of 2.5m by trapeze, wall, floor or channel mounting methods and will not exceed maximum loads as specified by the manufacturer.

Trays shall be supported at a maximum span of 2.5m by trapeze, wall, floor or channel mounting methods and will not exceed maximum loads as specified by the manufacturer.View More

Wire Basket Tray

Lionet basket type cable trays are normally made with galvanized steel wire welded into square or rectangular holes. Then it is powder coated or hot dipped finished.

Lionet basket type cable trays are normally made with galvanized steel wire welded into square or rectangular holes. Then it is powder coated or hot dipped finished. View More

Stainless Steel Wire Mesh Cable Tray

Here following please check spec for our general product.

Material:

Q235B Steel (Chinese standard steel /carbon steel), SS304, SS316 & SS316L

Surface Finish:

- Electro zinc plated – for indoor use to BS EN 12329-2000, 12microns thick.

- Powder coated - for indoor use to JG/T3045-1998, between 6 and 10 microns thick

- Hot Dipped Galvanized – for outdoor use to BS EN 1461-1999, between 60 and 80 microns thick

- Electrolytic Polishing – for stainless steel use

Dimensions:

Cable Tray dimensions are all internal. Available for customized.

Wire Mesh Cable Trays are constructed with a 50mm x 100mm mesh configuration.

50mm x 500mm mesh configuration are available

Depth of 25mm, 35mm,50mm, 60mm, 75mm, 100mm &150mm.(2")

Widths: 50~900mm.(2",4",6"8"10")

Lengthof 2997 fit max loading capacity in 40’ft containers

Diameters of wires are 4.0~ 6.0mm

Installation Notice:

- Bends, Risers, T Junctions, Crosses and Reducers can be made from wire mesh cable tray straight sections flexibly in projects.

- Trays shall be supported at a maximum span of 2.5m by trapeze, wall, floor or channel mounting methods and will not exceed maximum loads as specified by the manufacturer.

- Wire Mesh Cable Tray systems can be safely employed in places where the temperature ranges between -40°C and +150°C without any change to their characteristics

Application:

Wire Mesh Cable Trays are mainly used for low voltage, telecommunication, food industry and beverage industry,date center and fiber optic cables supported on short spans.

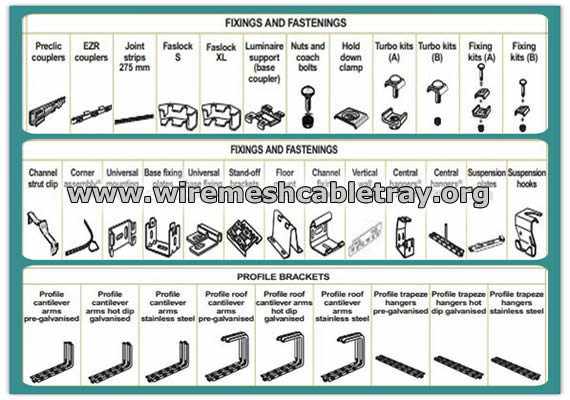

Accessories:

Features & Advantages:

All sharp ends are cut off to protect cables. Weight loading capacity is 27% stronger than traditional cable trays and cable ladders.

Wire Mesh Cable Tray Welding Strength Tests:

Test Description: Cutting off testing segment from wire mesh cable trays. Place the testing welded segment in hydraulic press and test.

Test Condition: 23±2°C, 50±5% RH, Hydraulic press speed: 5mm/min.

Result: Maximum broken force at least 1166N.