Get a quote today

Send your details inquiry on cable trays and get a response soon.

Wire Mesh Cable Tray Detailed Information

WIRE MESH CABLE TRAY Surface Finish

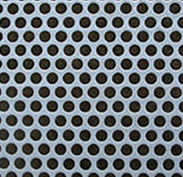

Perforated Cable Tray

It has three load carrying capabilities: Heavy Duty Return Flange, Medium Duty Return Flange and Light Duty. And offer a good ventilation to cables, are generally used for moderate heat generating electrical or telecommunication applications.

It has three load carrying capabilities: Heavy Duty Return Flange, Medium Duty Return Flange and Light Duty. And offer a good ventilation to cables, are generally used for moderate heat generating electrical or telecommunication applications. View More

Wire Mesh Cable Tray

Trays shall be supported at a maximum span of 2.5m by trapeze, wall, floor or channel mounting methods and will not exceed maximum loads as specified by the manufacturer.

Trays shall be supported at a maximum span of 2.5m by trapeze, wall, floor or channel mounting methods and will not exceed maximum loads as specified by the manufacturer.View More

Wire Basket Tray

Lionet basket type cable trays are normally made with galvanized steel wire welded into square or rectangular holes. Then it is powder coated or hot dipped finished.

Lionet basket type cable trays are normally made with galvanized steel wire welded into square or rectangular holes. Then it is powder coated or hot dipped finished. View More

Perforated Cable Tray

|

|

|

| Perforated Ladder Cable Guiding Device | Hot Dipped Galvanized Ladders | Round Perforated Steel Material |

Ladder style perforated cable tray is a kind of H line guild cover for electric cable wires. Lionet perforated ladder tray uses quality mild steel or aluminum or stainless steel sheet, slotted with round or custom holes. This is a welded metal form used for wire cable lining and protection in modern buildings.

Four common treatments applied for Lionet perforated ladder trays, and its specific uses:

Perforated ladder trays with electro galvanized surface: Suitable for indoor use to BS EN 12329-2000, 12microns thick;

Ladder perforated cable tray with powder coated surface: for indoor use to JG/T3045-1998, between 6 and 10 microns thick;

Perforated ladder tray with Hot Dipped Galvanized surface: for outdoor use to BS EN 1461-1999, between 60 and 80 microns thick

Stainless steel, electrolytic Polishing – for outdoor uses.

Benefits of Lionet Perforated Ladder Cable Trays:

1. Low cost, Less budget needed compared to standard traditional tray products.

2. Light in weight, wide range of sizes.

3. Fast heat dispersion.

4. Strong enough to withstand short circuits. Provides strength, rigidity without additional hardware.

5. Adapts to difficult architectural designs to accommodate changes in direction and elevation of cable runs.

6. Flexible, easy and fast installation. Design allows cable exit or entry at any point.

7. Cables can be secured to clamps or ties.

8. Various hardware accessories available to fix, support and install.

9.Safe smooth edge design to protect cable.

10. Easy for line check and cleaning , easy maintained.

All sharp ends are cut off to protect cables. Weight loading capacity is 27% stronger than traditional cable trays and cable ladders.